Racking System

TWO DIRECTIONAL LOCKING ARRANGEMENTS : OUR SPECIALTY

Our client list consists of a host of multinational companies, whom we cater to on a repeat and regular basis. As as a solution provider in efficient space optimization, our core competency lies in the designing custom-made solutions for various storage concepts, execution and installations.

Sailent Features of Racking :-

We follow IS standard 800/801 for the structural design of all sections (rack members) and FEM standard as operating standards. Our section designing is also approved by BUREAU VERITAS ISO 9001:2015 and Patent registration for TWO DIRECTIONAL LOCKING from Govt. of India- Design : Racks are designed at 1.75 Safety factor against minimum required as 1.55, hence our sections might be slightly over-designed if compared with others. However, we ensure the better life of products supplied by us despite of rough handling culture.

- Load beam: Load beam deflection at the center at the designed load does not exceed SPAN/340 against allowable SPAN/200 and Vertical columns are designed at a safety factor of 2.

• The Upright sections are formed on a purpose to built into a special "Unique" section. The front, as well as back face of the profile is punched with twin slots at 130mm pitch to accommodate the end connectors. No of bends in vertical sections varies from 6 to 12 nos depending on the requirements.

• Load beams are fabricated from twin rolled profiles interlocked to form a rectangular box section and welded at each end to a compatible steel connector, to effect the attachment to the upright frame.

• End Connector - All beams have a TWO DIRECTIONAL 5 hook end connector. The end connectors have a high degree of fixatives and is self backing types. - Quality Assurance : Test certificates for steel procured, structural design certifications, process inspection, pretreatment and coating check, Installation check by practical load test and Installation certificate

- Manufacturing Plant : We have manufacturing plants at Vasai and Chakan. These plants are equipped with all facilities including roll forming, shearing, bending, punching, MIG welding, pre-treatment and powder coating plants. All facilities are owned.

- Turn-Key Solution : Turn-Key Solution - Pallets, Racks, MHE and Rack Supported Warehouse, from concept till commissioning.

- Raw material : Steel grade FE410 / ST-34 DD quality suitable for roll forming, conventional forming, punching, Make - Jindal/Tata/Uttam

Types of Racking Systems :

Selective Pallet Racking System

This is our strong suit. We have executed such heavy duty as well as high volume and high rise projects nationwide, one with 18000 pallet positions being the largest by volume and size. There hasn’t been a single failure in rack structure in the past 15 years of our service. Load Carrying Capacity of the load beam is upto 5000kgs per level

Long Span Shelving Racking System

Multi Deep Racking System

Multi-Tier Racking System

Heavy, medium and light duty customized shelving systems with mezzanine/catwalk provisions at every 8.25 feet to utilize the maximum possible height of the warehouse/storage area where an individual can access various shelves by staircase and the material thereby can be accessed by other MHE’s, Goods Lift or Trolleys.

Cantilever Racking System

Drive In Racking System

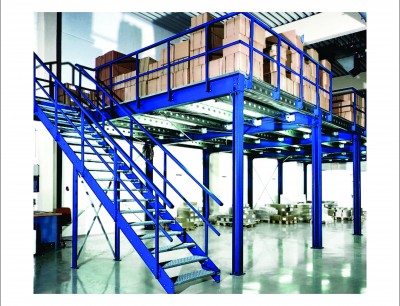

Mezzanine Racking System

Mezzanine floor Jorack Racking System is essentially a raised platform, that allows creating additional floor space from wasted air space, above existing work and storage areas, that may double or even triple the amount of space available.

Mezzanine floor can be used to create extra space for office, storage, production or even retail space.

Features and Spec:

- Probably the most cost-effective and efficient medium of significantly increasing the floor space and storage capacity.

- Capacity from 200 kg – 1500 kg per square meter.

- Supported by steel columns and it is totally independent of the host building.

- Fully dismantable and relocatable at a later date.

- Seamless integration within the existing environment.

- Light weight and economic steel structure.

- Flexible design option to meet precise customer requirements.

- Can be provided with goods lift as an option.

- High quality and powdered-coated accessories are available in a wide choice of colors.

- Can be provided with good ventilation and fire protection system.

- Can be easily relocated with minimal disruption.